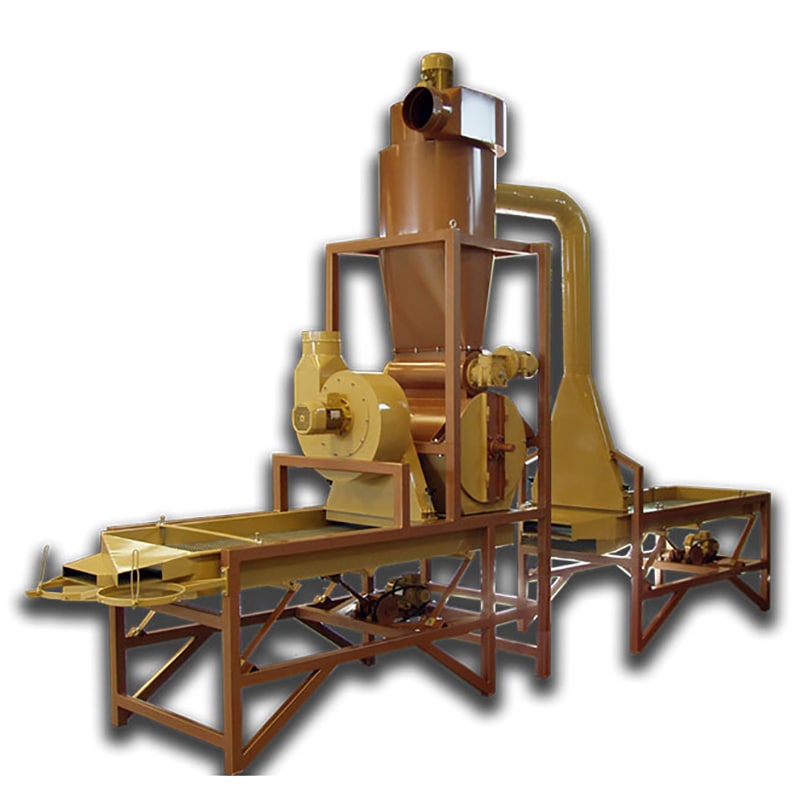

Peanut Cracking Shelling Machine

This machine is designed to crack, shell Peanuts. A complete peanut cracking machine, ideal for peanuts. The peanut cracking, shelling machine offered in several models with different capacities. Our latest design of peanut cracking, shelling machines offers flexibility in process plus gentle handling of peanut.

It does not need calibration of sizes before cracking, shelling.

Unstoppable without supervision of operation, with the minimum possible breakage.

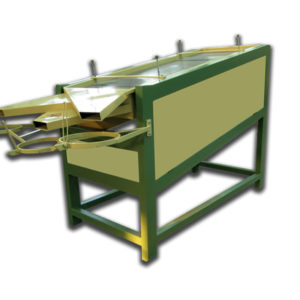

With adjustable feeding elevator, adaptive, changeable sieves, cleaners, air separators and fully variable adjustment of motors, everywhere.

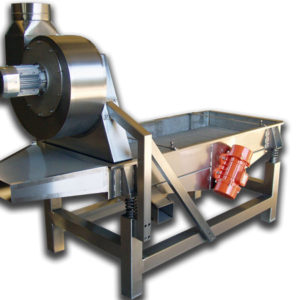

Mikropoulos Peanut Aspirators, are designed for product separation by density and aerodynamic profile. Multiple configurations available to provide optimum performance for your specific pre-cleaning or air-separation finishing needs.

The Mikropoulos Peanut Sheller cylinder is an integral part of the shelling machine with high efficiency, high capacity and minimum split creation. Easy of operation and low maintenance in mind. The peanut shelling grates are easy to change out. This quick change feature allows the operator to change the shelling grates quickly as the size of the peanuts change. Directly driven by its motor and gear reducer, the shelling cylinder will start under load. There are 4 hardened shelling bars in each cylinder. These shelling bars are readily adjustable to give the proper distance between the bars and the shelling grate. Also their rpm’s are fully adjustable.

TECHNICAL SPECS

| Type | Production | Power | Width | Length | Height |

| SF 200 | 100 – 200 kg/h | 4.5Kw | 1,3m | 3m | 1,90m |

| SF 500 | 400 – 600 Kg/h | 16Kw | 1,5m | 11m | 4m |